Laser Cutting

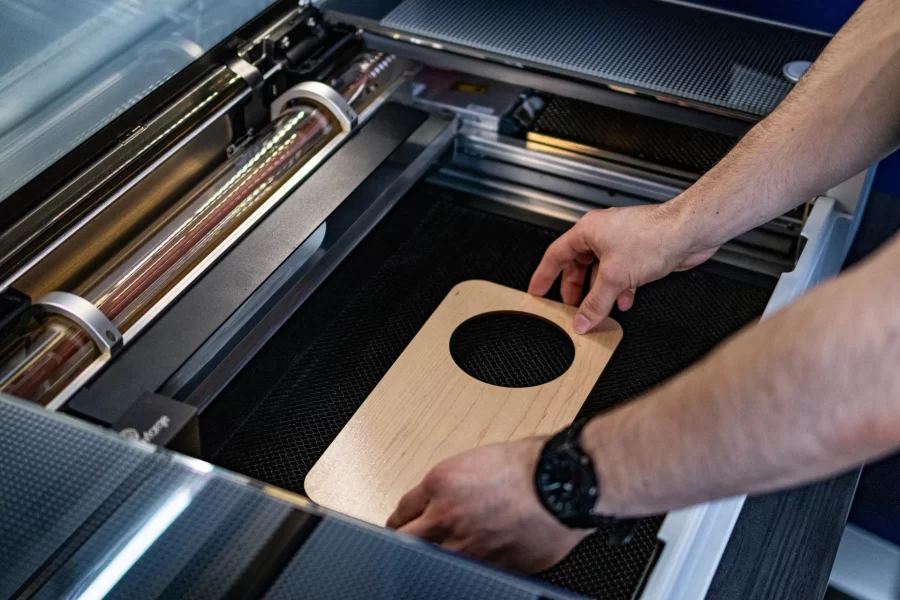

The VizLab has an xTool P3 laser cutter, with a working area of 18×36″. It can cut through materials that are up to 1″ thick. It’s controlled locally through xTool Studio software.

We also have a Glowforge Pro laser cutter, which has a working area of 12×20″ and uses Glowforge cloud software. We have a Glowforge Pro account with access to hundreds of designs.

Materials we can laser cut include MDF, wood, acrylic, leather, foam, and other lightweight materials. We can do light engraving on metals. We have our own materials, but it’s recommended that you bring materials with you (and bring extras for testing!).

Please see a staff member or student worker to get trained on the laser cutters!

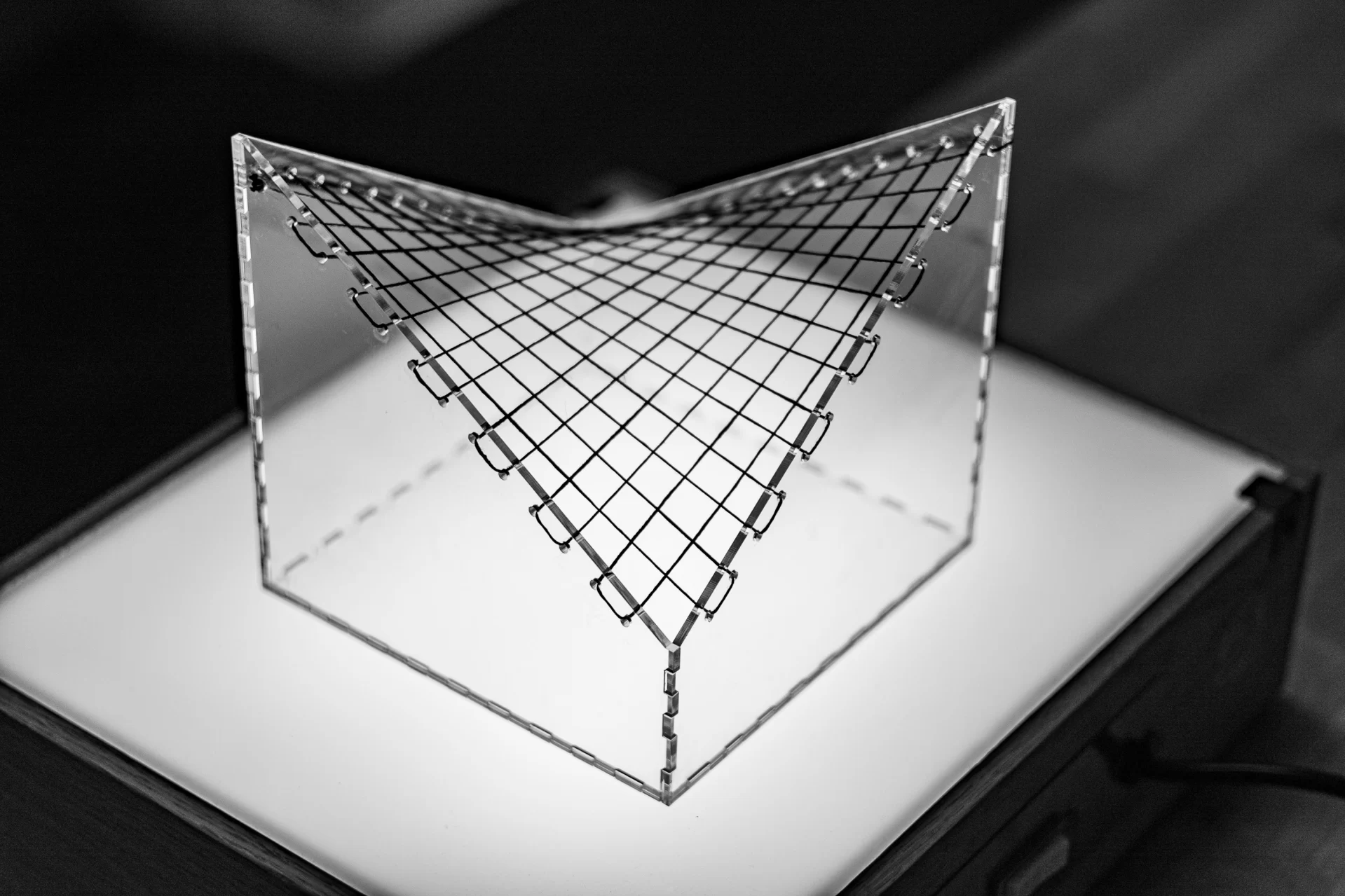

Yes, you can make 3D objects with the laser cutter! The frame for this hyperbolic paraboloid is made out of sheets of laser-cut acrylic that snap together.

Making and Finishing Station

The VizLab also provides a work area to polish up 3D printed and laser-cut objects. We have basic tools including wrenches, lubricant, glue, a dremel, hot air gun, tweezers, soldering iron, and sanding equipment.